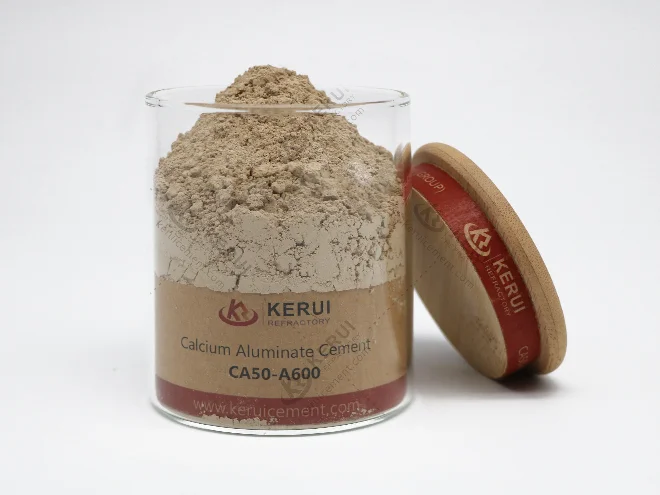

- Al2O3(%): 50

- Compressive Strength (72hrs) (MPa):55

- Final Setting Time (min): ≤360

- Al2O3(%): 51

- Compressive Strength (72hrs) (MPa):65

- Final Setting Time (min): ≤360

- Al2O3(%): 53.5

- Compressive Strength (72hrs) (MPa):72

- Final Setting Time (min): ≤360

- Al2O3(%): 68.5-70.5

- CaO(%): 28.5-30.5

- Compressive Strength (72hrs) (MPa):45-55

- Final Setting Time (min): 150-240

- Al2O3(%): 68.5-70.5

- CaO(%): 28.5-30.5

- Compressive Strength (72hrs) (MPa):45-55

- Final Setting Time (min): 240-330

- Al2O3(%): 74.5-75.5

- CaO(%): 23.5-25.5

- Compressive Strength (72hrs) (MPa):60-65

- Final Setting Time (min): 90-180

- Al2O3(%): 78.0-81.0

- CaO(%): 17.5-20.5

- Compressive Strength (72hrs) (MPa):40-50

- Final Setting Time (min): 90-180

- Al2O3(%): 78.0-81.0

- CaO(%): 17.5-20.5

- Compressive Strength (72hrs) (MPa):40-50

- Final Setting Time (min): 270-360

Applications Of Refractory Cement

-

Sintering Furnaces and Kilns

Sintering Furnaces and KilnsRefractory bricks are commonly used in the construction of sintering furnaces and kilns for ceramics, cement, lime, ore and other materials. They are able to withstand high temperatures for long periods of time.

-

Glass Furnaces

Glass FurnacesIn the glass manufacturing industry, refractory bricks are used to construct glass furnaces that require high temperatures to melt the glass feedstock.

-

Steel Smelting

Steel SmeltingIn the steel industry, refractory bricks are used to build blast furnaces, converters, electric arc furnaces and other smelting equipment to withstand high temperatures and chemical attack.

-

Coal Gasifiers and Chemical Industry

Coal Gasifiers and Chemical IndustryRefractory bricks are also used in coal gasifiers, chemical reactors and other chemical industry applications because these furnaces need to withstand high temperatures and corrosive chemicals.

-

Industrial High-temperature Furnace Body

Industrial High-temperature Furnace BodyRefractory bricks are often used to manufacture industrial furnace bodies, such as high-temperature smelting furnaces, incinerators, glass furnaces, steel furnaces, etc.

-

Coal gasifiers and chemical industry

Coal gasifiers and chemical industryRefractory bricks are also used in coal gasifiers, chemical reactors and other chemical industry applications because these furnaces need to withstand high temperatures and corrosive chemicals.

Certificates Of Kerui Refractory

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides,

Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

Kerui Refractory Products Packaging & Shipping

Kerui has high performance fire clay refractory cement and professional service commitment. You can rest assured to buy any refractory products from Kerui.

Customer Case Of Kerui Refractory

Besides mainland China, Kerui Refractory has exported products to more than 50 countries and regions across 5 continents across the world, including Asia, Europe, America, Africa and Oceania.

We have received recognition and high praise from customers all over the world, and are constantly receiving customers’ repeat orders and referrals.

-

5Continents

-

50+Continents

-

1700+Continents

-

4500+Continents